Waterless lithography on stone

Materials:

- silicone in tube

- turpentine

- turpentine insoluble drawing material (in this case toner)

Waterless lithography is an ecologic, clean and simple procedure, which is mainly associated with metal plates. The method of Nick Semenoff – the inventor of waterless lithography – described in “Waterless Lithography” by his student Jacob Semko, allows printing without the use water. In waterless lithography it is silicone diluted with turpentine that takes the function of grease repeller. A thin layer of ordinary silicone covering the plate repels ink just like water.

Waterless lithography is mainly associated with metal plates, but lithographic or marble stones can be used with this technique as well. The printing process goes the same way as with regular lithography – except the stone isn’t moistened.

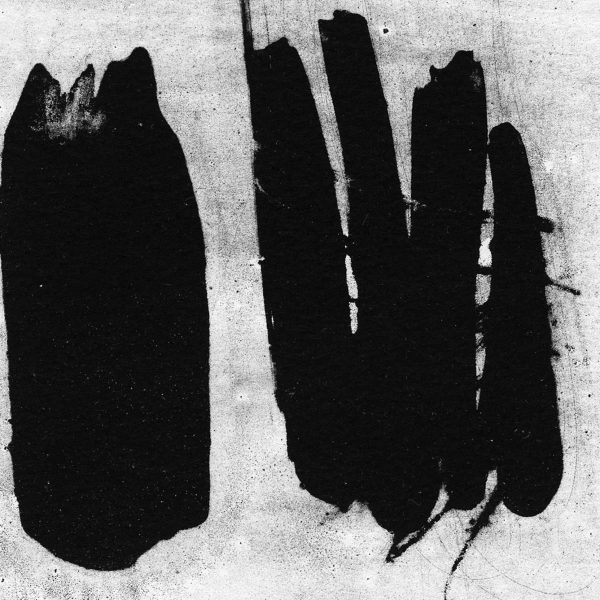

The prints shown above were prepared on a finely-grinded lithographic stone. An alcohol-based toner wash was made and fixed in a chamber filled with acetone vapors.

Then the drawings were evenly covered with a creamy mixture of turpentine and silicone. It took more than a day to dry.

Afterwards the drawing was removed with acetone and grease thoroughly removed with water and detergent. It is then very important to dry the stone in such a way that no mineral deposit is left that could take on ink.

Printing can be started right after the stone dries. During this process no water is used – silicone repels the greasy ink. Ink stiffness is important. If it is too fluid particles will break off and contaminate the non-printing surfaces. The ink must not be too hard either.